Lakeland Protects People. It’s what we do. Our products are used every day in a wide variety of industries as well as applications throughout the world. Used to ensure workers stay safe from harm by hazards including chemicals, flames and heat.

Our team can help you with any product information, quotes, or any general questions you may have about the product.

Fully-Encapsulating Coveralls for high-level chemical, dust and bio-hazard protection Lakeland’s PAPR suits combine fully-encapsulating protection against chemicals, hazardous dusts, and biological hazards, with the comfort derived from continuous breathing air and positive pressure supplied by a Portable Air-Purifying Respirator worn at the waste. The PAPR unit is belt-mounted and worn inside the suit (so isprotected as well as the wearer!), with filters connected through gaskets in the suit fabric. Air is fed into the hood via the units hose, with over-head or shoulder supply options. A semi-permeable neck-collar maintains air primarily in the hood where it is needed, allowing it filter to the rest of the suit, generating positive pressure to enhance protection. Exhaust valves allow the air to escape. The benefits of wearing a PAPR suit compared to coveralls or gas-tight suits are multiple:

EN 14126 is the standard for clothing used for protection against infective pathogens such as bacteria and virus. This standard is critical for assessment of garments used in medical crisis such as the Ebola outbreak in West Africa and the emergence of coronaviruses from Asia. It is important to understand that EN 14126 contains four tests to assess the resistance of garment fabric to penetration of agents containing contaminants such as blood and body fluids. Each test measures a different type of possible transmission. The tests a listed in the table below:- A common error is for manufacturers to list a classification for ISO 16603. This is evidently wrong – the standard states this clearly:- “The synthetic blood test (ISO 16603) is used for screening purposes, i.e. to predict the level where a strikethrough can be expected when performing the bacteriophage test9ISO 16604” Manufacturers should not use any classification based on an ISO 16603 test and users should not accept any classification of ISO 16603 tests as any indication of a protection level. More information about EN 14126 certification can be found in our fact sheet available here. MicroMax TS and ChemMax 1 to 3 fabrics all achieve the highest classes for tests listed in EN 14126

In many applications – especially in Oil, Gas and Petrochemical industries – workers need protection against flames & heat and chemicals. How can two types of protection be provided safely at the same time?

Secondary FR Workwear is designed to be worn OVER Primary FR Workwear (certified to EN 11612) to provide chemical protection without compromising thermal protection.

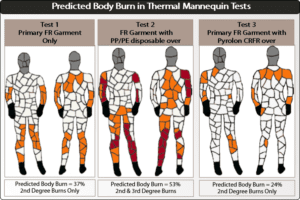

Standard disposable garments cannot be worn over Primary FR garments because, being based on thermoplastic polymers, they will ignite and burn, transferring heat through to the Primary FR Workwear and wearer and compromising the thermal protection. This has been proved through Thermal Mannequin Testing (according to EN 13506) which subjects garments to a flash fire and calculates predicted body burn.

Predicted Body Burn results in testing of a primary FR garment on its own and then with a standard PE/PP-based disposable coverall worn over it achieved the following results:-

In other words, tests 1 & 2 wearing standard polymer-based coverall OVER Primary FR Workwear results in an INCREASE in Predicted Body Burn.

Wearing effective Secondary FR Workwear instead of standard polymer-based coveralls will INCREASE thermal protection and result in a REDUCTION in Predicted Body Burn as in Test 3.

The following video compares the burn properties of different disposable coveralls and their relative predicted Body Burn Results in Thermal Mannequin Testing.

Download the brochure!

In other words, tests 1 & 2 wearing standard polymer-based coverall OVER Primary FR Workwear results in an INCREASE in Predicted Body Burn.

Wearing effective Secondary FR Workwear instead of standard polymer-based coveralls will INCREASE thermal protection and result in a REDUCTION in Predicted Body Burn as in Test 3.

The following video compares the burn properties of different disposable coveralls and their relative predicted Body Burn Results in Thermal Mannequin Testing.

Download the brochure!

There are three factors involved in selection of chemical suits and disposable protective clothing; protection, cost and comfort. Often comfort is seen as the poor relation of the other two. Protection must always remain the priority, cost must be minimised and comfort..? It’s nice if it can be achieved, but secondary to the others… And yet comfort is a safety issue. Uncomfortable garments are commonly not properly worn – perhaps the zip is left down to allow some breathability or some will tear holes on the fabric to improve comfort. When operators take such action, protection is compromised.

For this reason Lakeland developed Cool Suits – coveralls providing chemical protection through Type 4 to 6 and featuring breathability through design so enabling correct wearing of suits whilst maintaining protection where it matters. The video below shows how Cool Suits work.

Or download our Fact Sheet: The Cool Suit Principle [link: https://www.lakeland.com/uploads/catalogs/Europe/Fact-Sheet-The-Cool-Suit-Principle.pdf ]

Cool Suits offer chemical protection for Type 4, 5 and 6:

MicroMax NS Cool Suit: Type 5 & 6 protection with breathability MicroMax TS Cool Suit: Type 4 protection with breathability ChemMax1 & ChemMax 3 CoolSuits: Type 4 chemical protection with breathability Pyrolon CRFR Cool Suit: Type 4 chemical protection with breathability and Secondary FR properties

Lakeland ALM aluminised garments are designed for applications such as maintenance and repairs requiring work in proximity to high radiant and ambient heat.

There are three basic fabric types used for Type 5 & 6 garments: SMS Polypropylene and Microporous film laminates and flashspun polyethylene. Lakeland offer two garment ranges using SMS fabrics and Microporous film laminate variants. Standard and premium options are available for both Safegard and MicroMAX, the premium versions offer unique features and benefits.

Workers in a variety of industries such as oil, gas and petrochemical require protection against hazardous chemicals. Thousands of chemicals used as feedstock products, as catalysts in production systems or as products present a whole range of hazards – from immediate skin burns and irritation, high flammability through to long term health effects such as cancers, organ damage and damage to the unborn baby.

The fact of long term health hazards makes protection against chemicals more problematic than most workplace hazards that safety managers must address. Most hazards are relatively simple and straightforward; if a brick falls on a construction workers head the effect is immediate and a hard hat is the obvious solution; the consequences of a flash fire occur when it happens and are very evident – suitable FR workwear is the clear solution. Many chemicals however have no immediate effects.

If a wearer is contaminated he or she may not even be aware of it and may only become so months or even years later when the resulting cancers or other health effects become apparent… and those consequences are commonly catastrophic and often lethal. Furthermore, depending on the chemical those consequences may result from very small volumes of a chemical; toxicity is measured in micrograms – which is why chemical protection is assessed through permeation which deals with very small amounts of liquids.

So makes the fact that probably the most common misunderstanding in the PPE industry relates to chemical permeation somewhat surprising – though understandable. Most users assess suitability of chemical protection by referring to chemical permeation test breakthrough, the result of a test which measures permeation resistance of chemical suit fabric to a specific chemical, the result often quoted as a “breakthrough” of >480 Minutes.

Most users interpret this as “None of the chemical has permeated through the fabric in 480 minutes therefore I can safely use the suit for up to 480 minutes”

Unfortunately this is not what “breakthrough” in this case means. In fact the test is measuring a time until the RATE (or (SPEED) of permeation reaches a specific level (usually 1.0µg/min/cm2). So “breakthrough” does not mean none of the chemical has broken through at all – in fact at the point of breakthrough the chemical has already been permeating through the fabric for some time – as indicated by the graph below.

So those selecting chemical suits should not rely solely on permeation test data; chemical may have permeated through the fabric well BEFORE the breakthrough and in the case of chemicals with high toxicity and long term effects this could be critical. The widespread use of test “breakthrough” to indicate safe-use time for chemical suits in a misunderstanding – probably the biggest – and potentially the most dangerous – in the PPE industry.

Lakeland supply a range of chemical suits. ChemMax® 3, ChemMax® 4 Plus and Interceptor® Plus work with Permasure® - Lakeland free-to-use smartphone app that calculates safe-wear times based on permeation rates and the toxicity of over 4000 chemicals. You can download more about Permasure® from the page below.

If you would like to talk to a member of our team, please contact us using the details adjacent.

OSE Directory

Oxford Court The Granby

Weymouth

DT4 9GH

England

Get the newsletter - Keep up to date with Health, Safety & Environmental monitoring products from across the globe with our free newsletter