There are no PDF's for this product

For more than 60 years, GfG has been committed to protecting people, industrial facilities and the environment by developing and manufacturing gas detection systems. With an extensive range of portable gas detectors and fixed gas detection systems, GfG can supply you with a selection of products for many applications and industries. Our scope also includes on-site service and advanced training courses.

We are specialists for gas detection solutions, not generalists in safety. No one can be the best at everything, but if you focus on one thing, you can achieve excellence. We work hard to provide you with the best gas detection equipment available, so you can focus on your task without having to worry about the risks that gases can pose. Because of that we invest more heavily in research and development than any other company. Approximately 13% of our annual turnover is reinvested in basic research and the development of new sensors and devices.

This includes finding solutions for customers whose requirements are not met by “off the shelf” products. We take pride in our longstanding cooperation with the Singapore Civil Defence Force (SCDF), for example. For many years now, they have put their trust in GfG’s portable devices, which we optimized to adapt to the Singaporean climate and fulfill the special requirements for integration into the SCDF communication network.

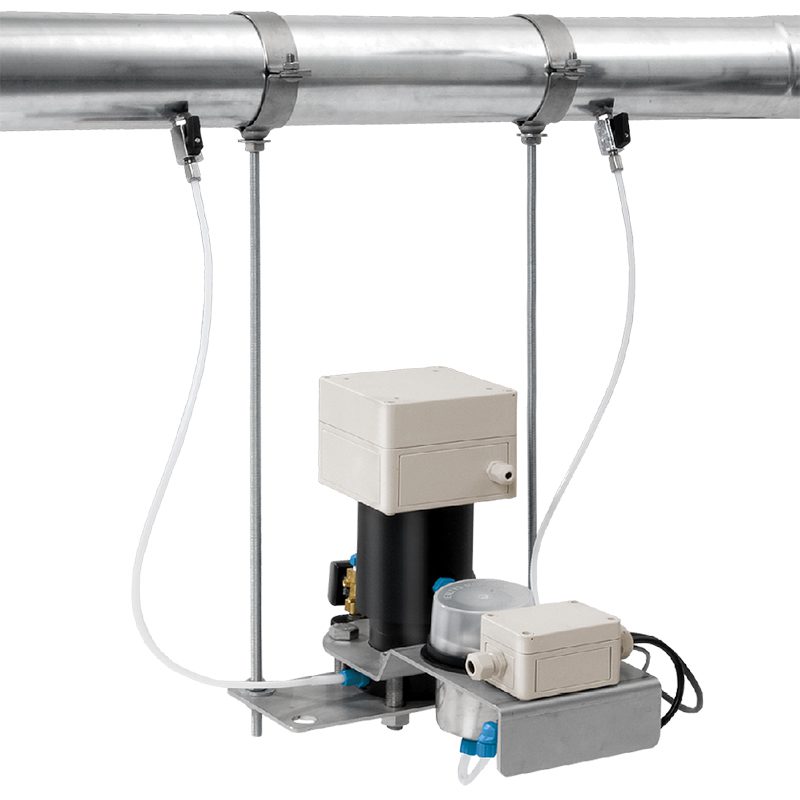

A partial flow of the medium is guided through the MiniCal III bypass fitting and pumped back into the pipeline. This means that the installation location can be selected flexibly. Depending on the local conditions, the fitting is mounted either below the pipeline or on the wall.

A requirement for the early detection of an ammonia leakage is the regular exchange of the medium in the measuring chamber. A partial flow of the medium is passed through the fitting as soon as the upstream solenoid valve opens. By setting the interval and the opening time of the solenoid valve, a regular exchange is achieved. After the measurement, the medium is pumped back into the circuit by a high-pressure pump to avoid coolant losses.

The monitoring of the pump and the solenoid valve allow a control of the flow. The bypass fitting is designed for a pressure range of 1 to 6/10 bar and a temperature range of -10°C to +50°C.

Would you like to know more?

Would you like to know more?

Our team can help you with any product information, quotes, or any general questions you may have about the product.

Putting the ‘direct’ in directory since 2009. With our global catalogue of quality safety and environmental monitoring products all under one roof, we put an end to lengthy, saturated searches. At OSE, just find and enquire and we will put you in touch with the right person to make your product purchase.

"*" indicates required fields