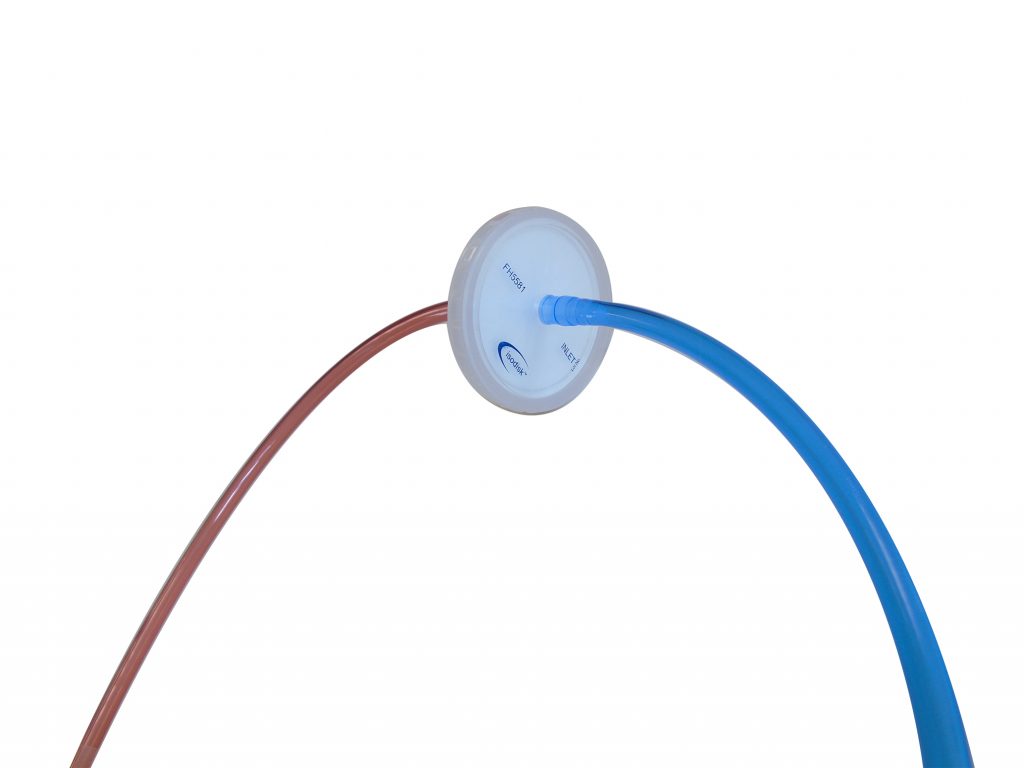

Helapet custom manufacture disposable in-line disc filters, used for the vital protection of sensitive instrumentation from the risk of particulates and micro-contamination. Each filter is produced in an ISO Class 8 rated cleanroom, combining a variety of filter media contained in a circular polymer capsule with a selection of inlet/outlet connectors. Our filters are used for a variety of equipment protection applications. Including gas venting, liquid clarification and particle filtration.

Low linting, clean and able to withstand intense heat and pressure, we also offer Tampo brand printing allowing clients to add whatever information they wish directly onto the filter in a range of colours:

Client services include:

In-process consultancy

We pride ourselves on offering a consultancy based manufacturing service. Working closely with our clients and using CAD software to create the best filter designs.

Sampling

We can produce prototype sample on each new filter product for you to test before proceeding to manufacture.

Sterilisation

Our expert knowledge means we can supply our filters non-sterile or sterilised by Ethylene Oxide (ETO).

Testing and validation

We offer clients a number of test methods to validate our filter performance

Helapet offer unrivalled quality in the design and manufacture of our inline disc filters, both as off-the-shelf products or custom made specials. We supply filters for OEM and end-user applications in a wide range of markets including pharmaceutical, environmental monitoring, print, food and drink and electronics.Our Vari-Disk® Service allows clients to select from a wide range of filter media, inlet / outlet connectors and housing sizes to best suit individual filtration requirements.

4 step method to design your unique filter:

1. Select a suitable filter media for your application

We include a comprehensive range of media including PTFE, PES,

HEPA and Nylon in various micron ratings to optimise filtration,

compatibility and flow rates

2. Select the best filter diameter

Choose from 24mm, 25mm or 50mm sizes to maximise through-put

Volume

3. Select inlet / outlet connections for your filter

Our extensive range of connectors gives us the versatility to securely

connect to a wide range of instrumentation and equipment Includes

Hose Barb, Luer Lock and Pipe Thread options

4. Decide on any printed information or branding

Our OEM service includes the ability to print branding, company logos

of information directly onto the filter design in various ink colours.

Would you like to know more?

Would you like to know more?

Our team can help you with any product information, quotes, or any general questions you may have about the product.

Putting the ‘direct’ in directory since 2009. With our global catalogue of quality safety and environmental monitoring products all under one roof, we put an end to lengthy, saturated searches. At OSE, just find and enquire and we will put you in touch with the right person to make your product purchase.

"*" indicates required fields